LehmKur - Rammed earth walls for multi-storey residential buildings

Short Description

Starting point / motivation

The building sector and construction industry are responsible for an estimated 37% of global energy and process-related CO2 emissions. In addition, around 50% of all resources extracted are required for the construction of buildings. The massive use in recent decades of materials that can only be reused by means of downcycling or that are sent to landfill also poses major challenges and burdens for the construction sector.

At the same time, a considerable amount of excavated material ends up in landfill sites after a long transport. This is usually soil that has been created over many thousands of years and can be used as a building material without high energy consumption.

In order to achieve the necessary change in the construction sector, energy and emission-intensive building materials must be replaced by resource-conserving, recyclable materials that are produced without high energy consumption. As a geobased resource, clay meets all of these requirements and can therefore make a major contribution to climate-neutral construction.

Contents and goals

The aim of the project is to create a planning and data basis for the construction of multi-storey residential buildings using innovative construction methods with the use of excavated material.

Up to now, rammed earth construction has only been used for prestigious buildings due to the high amount of work involved. The aim is to also use rammed earth in large-volume residential construction. By using material directly on site and reducing transportation costs, resource consumption and CO2 emissions can be kept to a minimum. In addition, clay can be reused without restriction.

The reduction of transport-induced CO2 emissions, waste generation on the construction site and the use of CO2-intensive building materials through the use of excavated material as a building material supports national efforts to achieve climate targets.

Methods

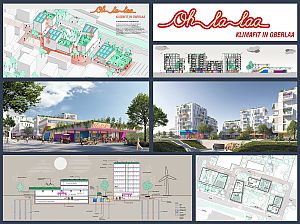

The architecture offices WUP and g.o.y.a., together with the property developer GEWOG, have won a competition organized by the wohnfonds_wien for a building site in Kurbadstraße.

An innovative construction method is to be used: a load-bearing structure made of sparingly used reinforced concrete with non-load-bearing timber rammed earth components as the wall-forming material, which takes on the function of thermal, sound and fire-protection. This construction method makes it possible to reduce CO2 emissions caused by the building material while at the same time increasing comfort in the interior.

The planned approach requires an intensive examination of logistical, building physics, material technology and social science issues, which are to be addressed as part of the research project.

Expected results

The knowledge gained from the project should form the basis for other buildings constructed using this method.

Accompanying the project with building ecology calculations, taking into account different design variants, shows possible levers for reducing greenhouse gas emissions when selecting building materials in multi-storey residential construction.

Project Partners

Project management

IBO - Österreichisches Institut für Baubiologie und -ökologie

Project partners

- GEWOG - Gemeinnützige Wohnungsbau-Gesellschaft m.b.H.

- WUP ZT GmbH

- g.o.y.a. Ziviltechniker GmbH

Contact Address

DI Ute Muñoz-Czerny

Alserbachstraße 5/8

A-1090 Vienna

Tel.: +43 (699) 1319 20 21

E-mail: ute.munoz@ibo.at

Web: www.ibo.at